Specs at a glance

-

Process temperature

-50 °C...+150 °C

(-58 °F...+302 °F)

up to 230 °C / 450°F on request -

Process pressure / max. overpressure limit

Vacuum...40 bar

(Vacuum...580 psi) -

Min. density of medium

0.5g/cm³ (0.4g/cm³ optional)

Field of application

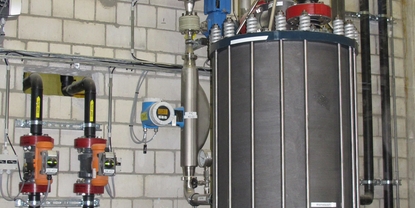

Liquiphant FTL51C is a point level switch with extension tube and highly corrosion resistant coating. For use in hazardous areas with all international certificates. Useable in all industries. FTL51 offers functional safety SIL2/SIL3. With the second line of defense highest degree of safety and availability of the device can be guaranteed. Reliable measurement values, not affected by: changing media properties, flow, turbulences, gas bubbles, foam, vibrations or build-up.

Point level switch for all liquids with highly corrosion-resistant coating.

Process connections: Flanges and hygienic process connection (FDA conform with PFA)

Temperature: -50 to +150°C (-58 to +302°F)

Pressure: -1 to +40bar (-14.5 to +580psi)

Sensor material: ECTFE, PFA (Edlon, Rubyred, conductive), Enamel

International explosion protection certificates, overfill protection WHG, SIL, hygienic certificates, marine approvals

Benefits

Use in safety systems requiring functional safety to SIL2/SIL3 in accordance with

IEC 61508/IEC 61511-1Different plastic coating (PFA) and enamel coating for applications with aggressive medias

International explosion protection certificates and overfill protection certificate (WHG)

No calibration required, easy to start up

No mechanically moving parts: no maintenance, no wear, long operating life.

Monitoring of fork for damage: guaranteed functionSecond line of defense to protect the environment

Variety of standardized process connections for all applications

Videos

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Predecessor

-

-

Technical Information (TI)

Liquiphant M FTL51C Technical Information

Point level switch for all kinds of liquids

with high corrosion-resistant coatingEN 31/08/201813/02/201719/05/201029/11/2007Language:

English

Version:

31/08/2018

File size:

2 MB

File name:

TI00347FEN_1418.pdf

-

-

-

Technical Information (TI)

Technical Information Liquiphant M Density and Density Computer FML621

Density computer for liquids

Also for use in hazardous areasEN 08/10/201212/02/200929/11/2007Language:

English

Version:

08/10/2012

File size:

800.4 KB

File name:

TI00420FEN_1312.pdf

-

-

-

Operating Instruction (BA)

Liquiphant M/S FTL50, FTL51, FTL50H, FTL51H, FTL51C, FTL70, FTL71 Electronic insert FEL50A PA

Vibration Limit Switch

Level limit switch for all liquids.

Suitable for use in hazardous areas, food and pharmaceuticalsEN 10/08/2004Language:

English

Version:

10/08/2004

File size:

836 KB

File name:

BA141FEN.pdf

-

-

-

Short Instruction (KA)

Bedienungsanleitung/ Operating Instuction Liquiphant.

Sliding Sleeve

EN 01/05/200801/11/1998Language:

English

Version:

01/05/2008

File size:

314.8 KB

File name:

KA100fa6_0308.pdf

-

-

-

Short Instruction (KA)

FTL5x - sealing set

FTL5x - sealing set

EN 03/05/2021Language:

English

Version:

03/05/2021

File size:

63.3 KB

File name:

KA00609F_A2.pdf

-

-

-

Short Instruction (KA)

Liquiphant M FTL50, FTL51 Operating Instructions

Point level switch for all kinds of liquids

EN 20/01/201729/06/201618/04/200601/04/2006Language:

English

Version:

20/01/2017

File size:

982.5 KB

File name:

KA00143FA6_1417.pdf

-

-

-

Short Instruction (KA)

FTL5x - Exchange of housing F13

Liquiphant FTL5x - Exchange of housing F13

EN 15/04/2021Language:

English

Version:

15/04/2021

File size:

232.8 KB

File name:

KA00531F00_A2.pdf

-

-

-

Short Instruction (KA)

Exchange of sensor on Liquiphant M/S

Exchange of sensor on Liquiphant M/S

EN 24/04/2012Language:

English

Version:

24/04/2012

File size:

398.2 KB

File name:

KA00529FA2_0908.pdf

-

-

-

Short Instruction (KA)

Liquiphant M Density FTL51C Operating Instructions

Liquiphant M for density and concentration calculation

EN 29/06/201615/11/2007Language:

English

Version:

29/06/2016

File size:

905.3 KB

File name:

KA00286FA6_1316.pdf

-

-

-

Short Instruction (KA)

Bedienungsanleitung/ Operating Instuctions Liquiphant M/S + FEL57

Selbsttest

Self testEN 27/02/201701/03/2002Language:

English

Version:

27/02/2017

File size:

227.1 KB

File name:

KA00147FA6_1316.pdf

-